SEMI Auto LED Bulb Eyelet Machine with E27 E14 Cap and 1000~2000 PCS Per Hour Capacity

Pick And Place Machine

MOQ :10 piece

Lead Time :30 Days

Seller Support : Trade Authenticity Guaranteed & Accepting

Payment : T/T,Credit Card,Other

Departure Port : Ningbo, Shenzhen

Product details

Product Specifications

- Brand name:HUAQI ZHENGBANG

Product Description

ZB series placement machine main features:Small volume,easy operate, run stable and price affordable. They can mount 0402, 0603, 0805, 1206, 1210, 3528, 5050, SOP and QFN etc chips precise. These machine can help to avoid the unstable performance because of manual mounting and reduce the rent cost, improve the product capacity at the same time.

System | Project | Content |

Mounting system | Mounting numbers | 2pcs |

Mounting precision | 0.025mm | |

Mounding angle | 0~360° | |

Theoretical speed | 6500pcs/h | |

Normal SMT | 5000pcs/h | |

Nozzle type | Juki series nozzle | |

Applicable element | RC(0402、0603、0805、1206 etc) | |

LED Lamp beads(0603、0805、3014、5050 etc) | ||

Chip(SOT、SOP、QFN、BGA etc) | ||

PCB | PCB minimal size | 10×10 mm |

PCB maximum size | 320×450 mm | |

PCB thickness | ≤2mm | |

PCB warping allowable value | <1mm | |

Feeder tank | 8mm | 20pcs |

12mm | 4pcs | |

16mm | 2pcs | |

24mm | 1pc | |

Preposition IC material level | 8pcs | |

Tubular materials feeder | ZhengBang dedicated Five tubular materials feeder one(optional) | |

X/Y/Z axis | X/Y axis moving range | 410×490 mm |

Z axis moving range | 10 mm | |

Z axis rotation angle | 0~360° | |

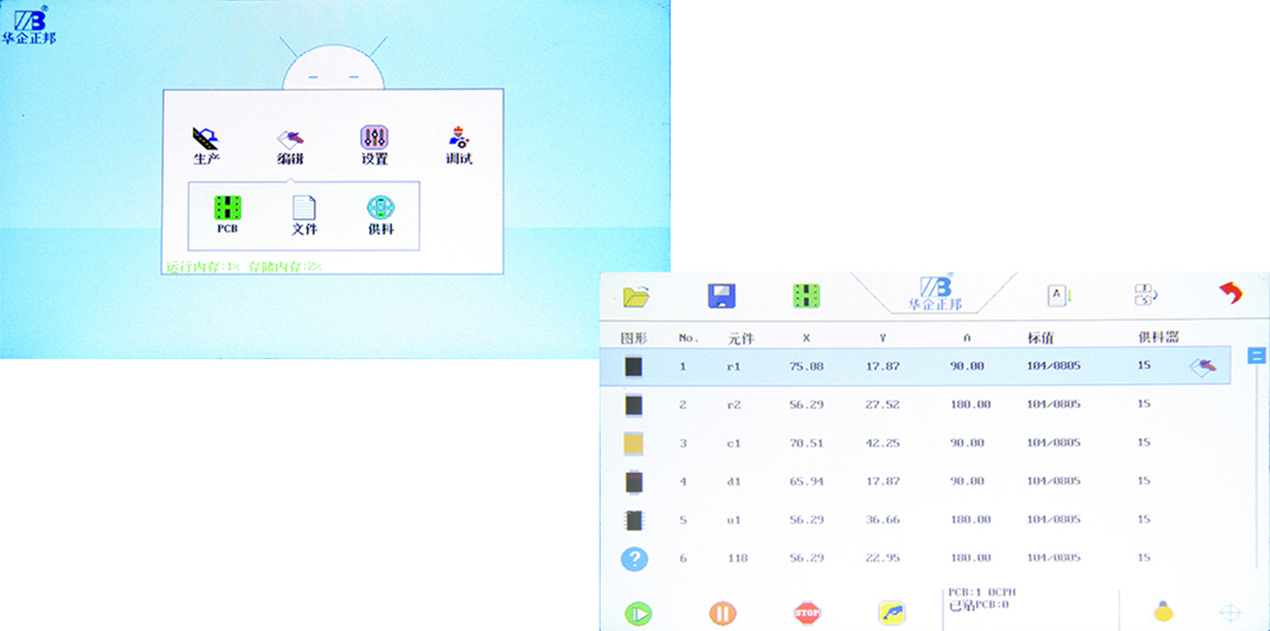

Control system | Operational software | Embedded HRM system |

Compatible file format | CSV、TXT.format | |

Program method | Researching and development independently | |

Basic parameter | Air pressure | 0.4 Mpa(the built-in pump) |

Vacuity degree | -92kpa | |

Storage | 8G(Kingston SD card) | |

Power | 150 W | |

Power supply | AC220V±10% 50Hz | |

Main engine outline size | L 800 × W 780 × H 380 mm | |

Materials feeder outline size | L 235 × W 700 × H 245 mm | |

Net weight | 56kg | |

Gross weight | 83kg | |

Outline package size | 1160*845*532mm |

Powerful System Upgrade

Providing PCB original file convert the coordinate file then start producing directly. Don’t need to through other software for converting.East to learn, understand and operate, quick start in half an hour.Chinese/English switch. Inner system don’t need extra computer, which save cost.

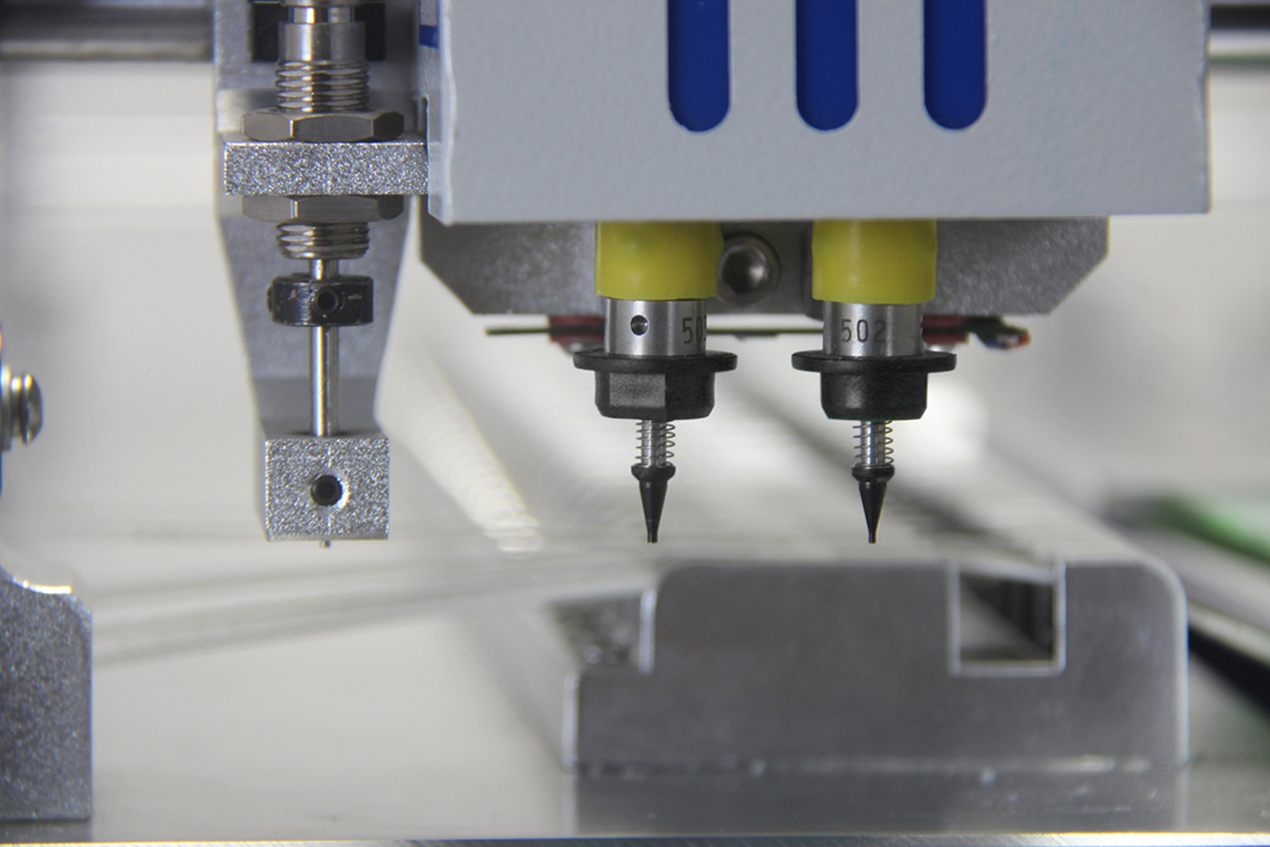

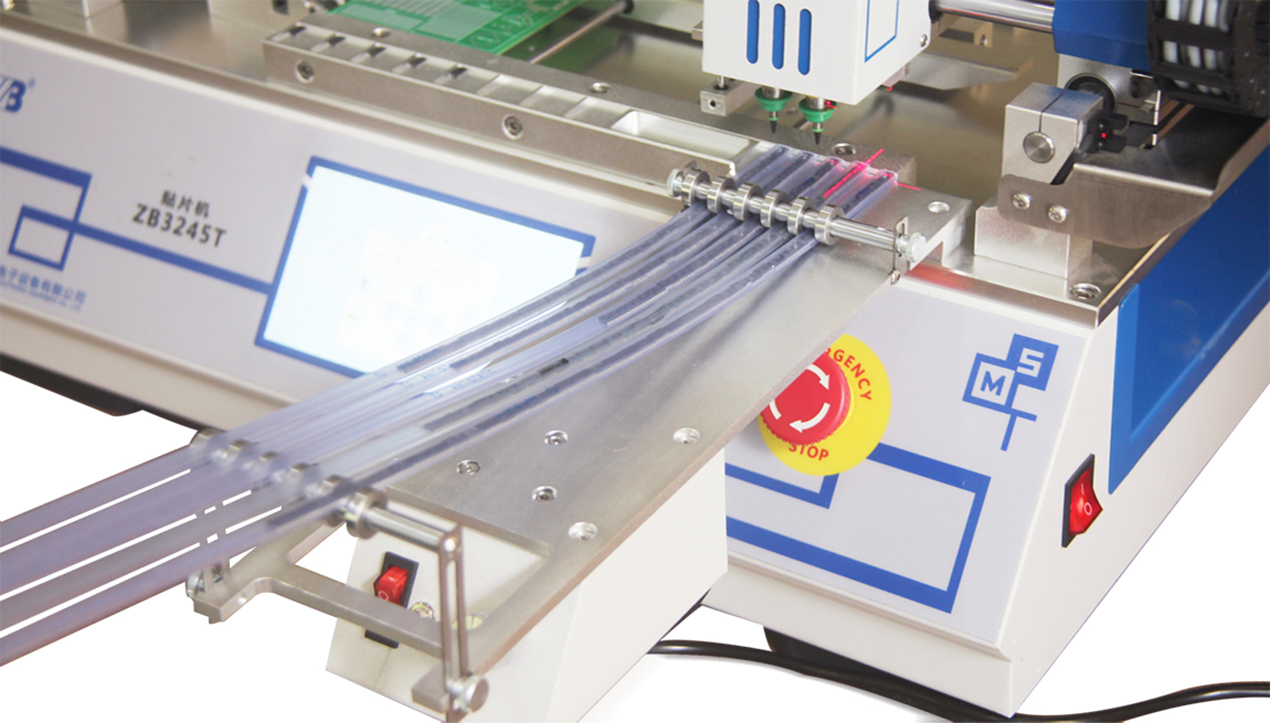

Mounting Head

Dual mounting heads 360 degrees rotate by any angles Integration IC mounting at the same time. High precision JUKI series nozzle.

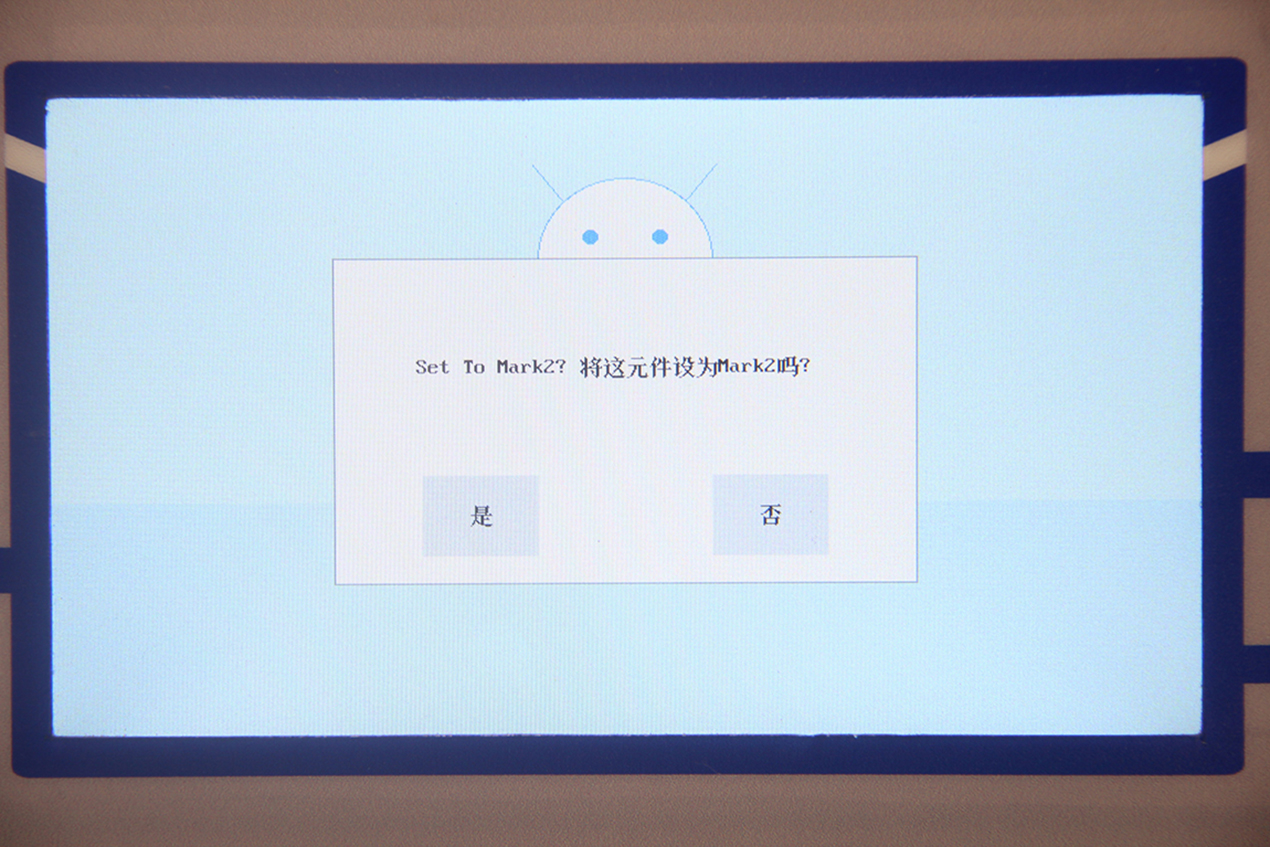

Dual Mark Point Recognition

Dual Mark point positioning function. Adjust PCB nonstandard and the PCB not right or offset problems.

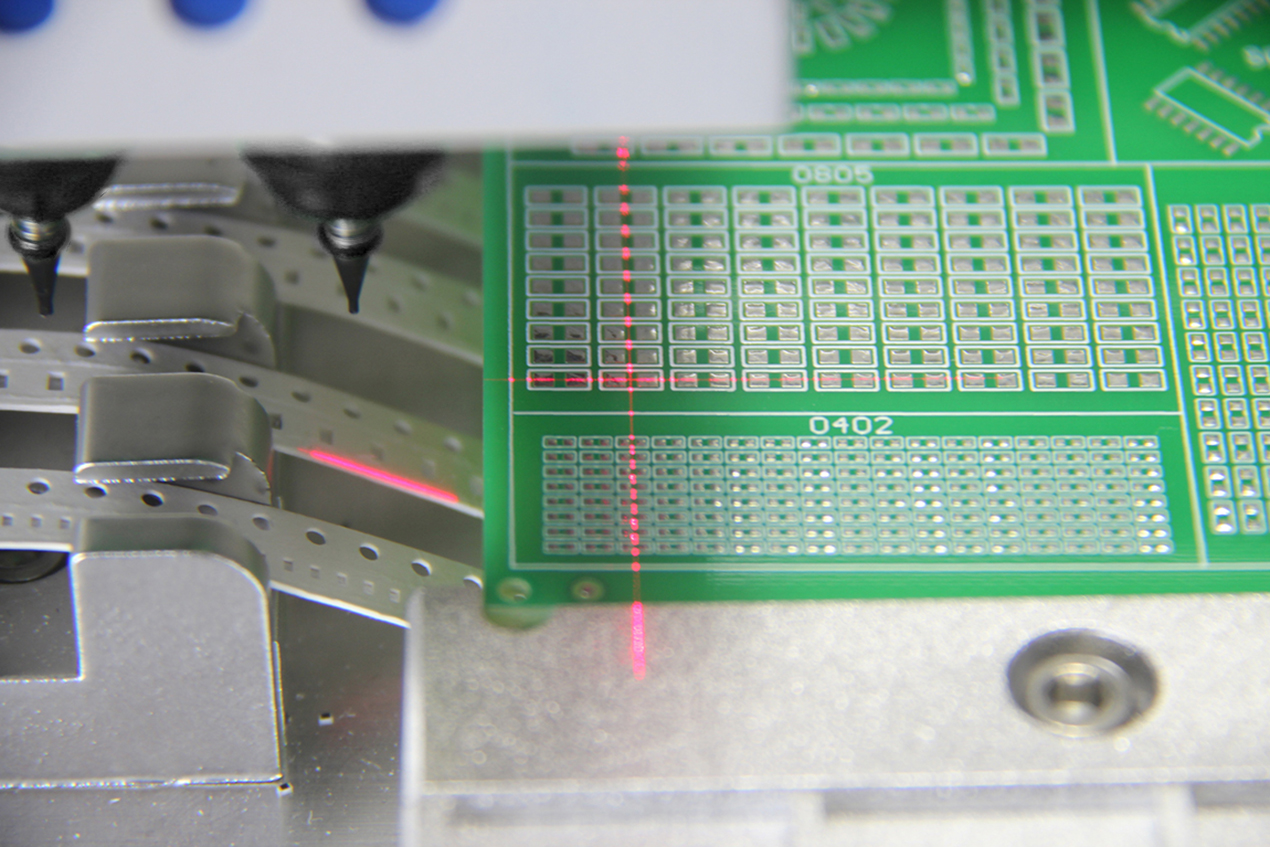

Laser Positiong

Cross laser positioning, visual adjust the coordinate.

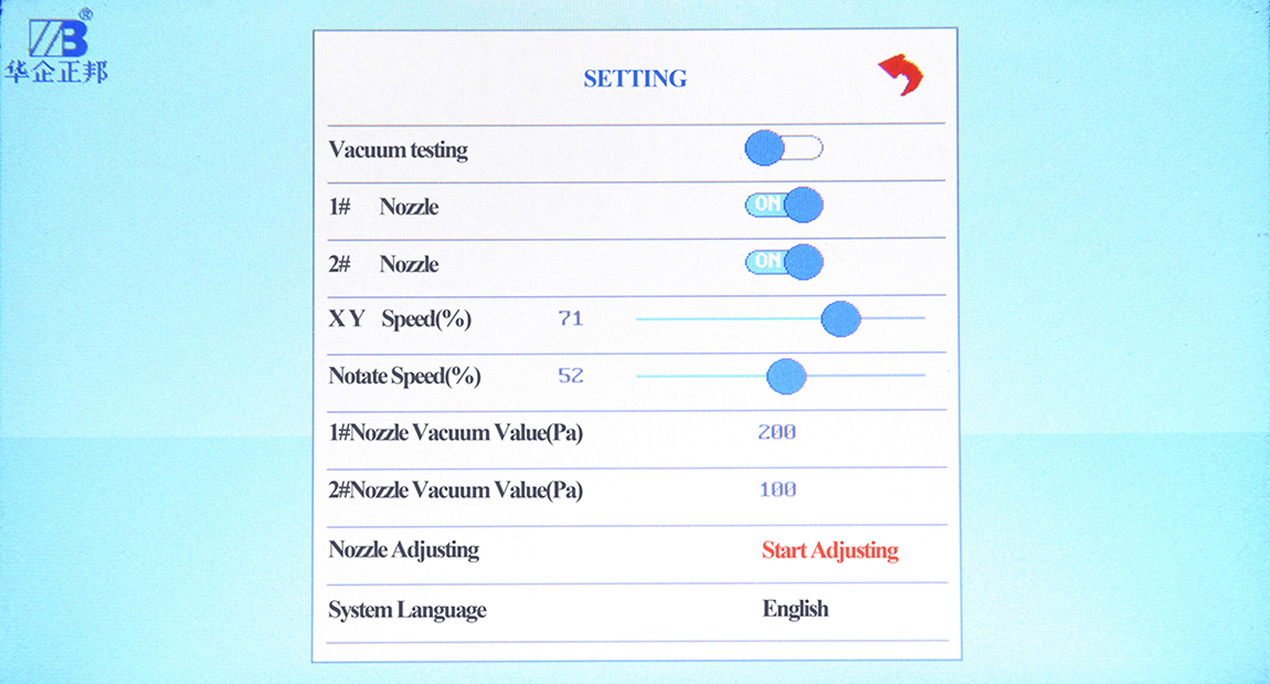

Vacuum Test

Vacuum negative pressure detection, automatic supplement materials.

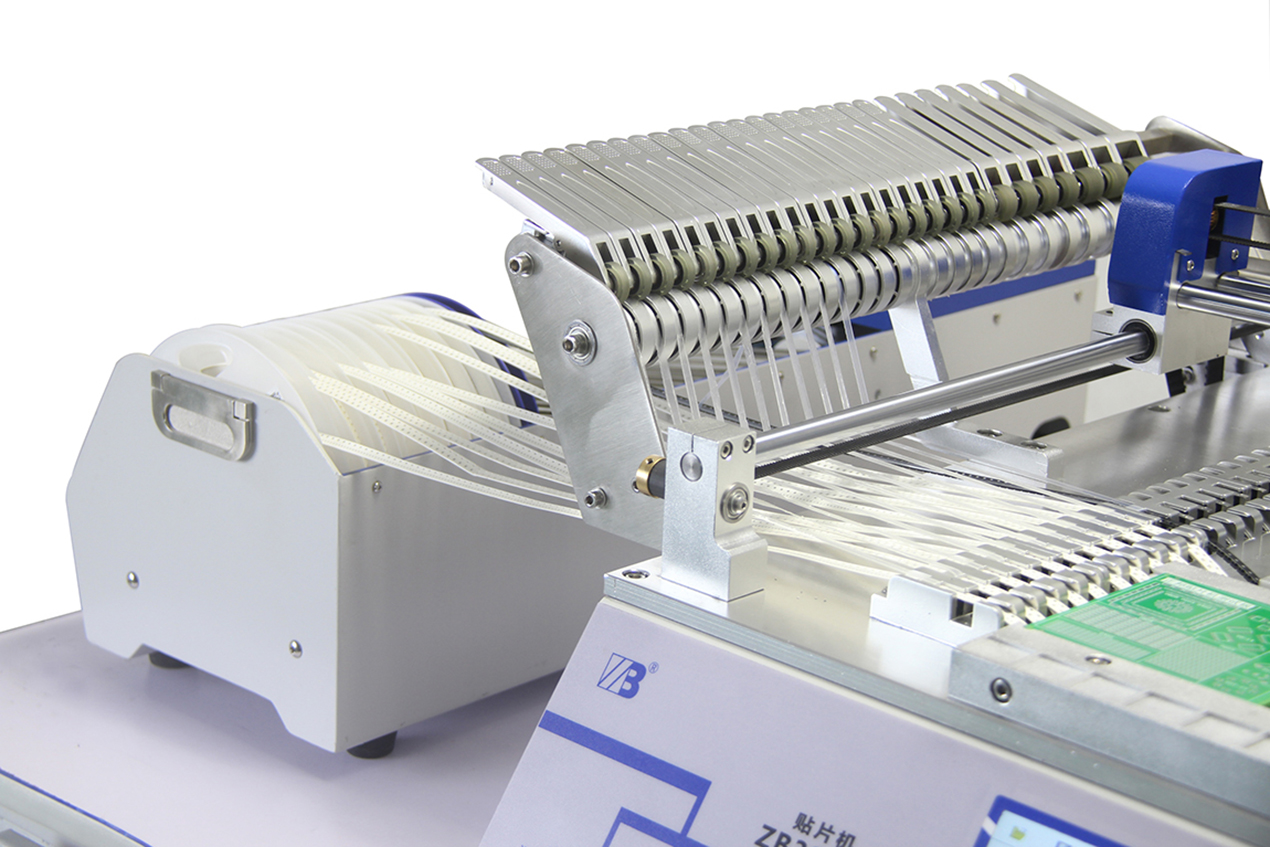

Feeding Device

Exclusive patent, automatic, stripping materials membrane, satisfy most mounting requirements.

Vibration tube feeder

FIVE vibrate tubular materials feeder (optional). Satisfy several IC tubular materials, producing mounting require.

The Control Panel

7 inch high definition LCD touch display screen, operation panel for operate easily.

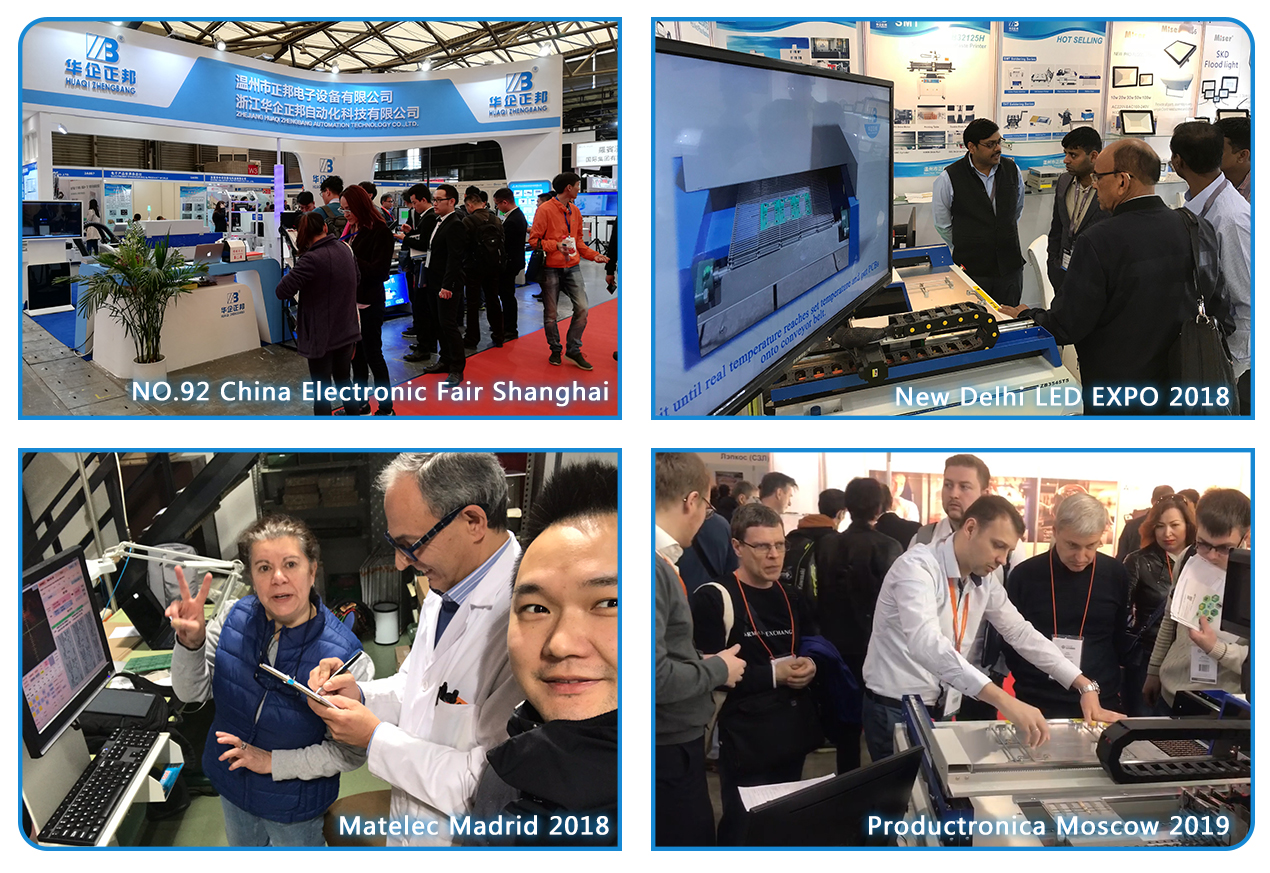

Wenzhou Zhengbang Electronic Equipment Co., Ltd. Established in 2006, Wenzhou Zhengbang Electronic Equipment Co., Ltd is a professional manufacturer of machine and assembly line accessories as the THT welding equipment series, SMT welding equipment series and Assembly line series. It serves more than two hundred thoudsand customers.

Our products have been sold well in China and all over the world. Our main export countries and regions include North America, South America, Europe, Southeast Asia, Africa and Middle East nearly 60 countries. Insisting to the operational principle of “Quality first, Customers first”. All our staff are ready to serve you with our best efforts. We could provide you the highly competitive prices and reliable quality.

1. In case the machine breaks down, where can I find the spare parts?

Once your machine have the problem, please contact me or leave a message to my email. I will forward your message to our engineers and within 24 hours we will arrange

inspection for your machine remotely.

If it needs replacing any spare parts, we will send it to you directly by TNT,DHL or others.

We have the technical teams in some area. If you need local service, you have to cover the travel expenses, labor cost. They will provide service for you directly.

The machine will be packed with some spare parts according to our experience.

2. Payment term?

We accept:T/T, VISA, PAYPAL, WEST UNION, BANK TRANSFER, ONLINE BANK PAYMENT

3. What about the lead time?

1~2 weeks after we received the payment, we will start the delivery. For customized order, it depends on practical situation.

4. How about the Training ?

We provide the online remote training service, and we will offer you the operating video and manual for users’ repeatedly learning.

5. What’s the applicative component size for this machine?

Minimum component size: 0402.

maximum size: lead pitch no more than 0.5mm, such as QFP100.

Components height:<5mm.

6.Which nozzle suit for the component?

Machine used YAHAMA series nozzle.

size 500 nozzle:1005,1608,2012.component minimum width:0.45mm to 1.45mm.

Size 501 nozzle:0603,0402.component minimum width :below 0.45mm

Size 502 nozzle:0805,1005,1608,2012.component minimum width:0.45mm to 0.75mm.

Size 503 nozzle:0805,1206,1608,2012.component minimum width:0.75mm to 1.45mm.

Size 504 nozzle:2012,3216,SOT23.component minimum width:1.1mm to 2.5mm.

Size 505 nozzle:component minimum width:2.5mm to 4mm.

Size 506 nozzle:component minimum width:4mm to 7mm.

If you could not find any similar items you want, you may send some photos to us. because our catalog and website haven't included all of our products.

You May Like

- Exhibitor

- Free Member

- Trade Assurance

Company Location: ZHE JIANG

You May Like

-

SEMI Auto LED Bulb Eyelet Machine with E27 E14 Cap and 1000~2000 PCS Per Hour Capacity

-

SEMI Auto LED Bulb Capping Machine with E27 Cap and 600~750 PCS Per Hour Capacity Fast Change

-

Full Auto LED Bulb Assembly Machine with E27 E14 B22 Cap and 1200~1500 Per Hour Capacity Fast Change

-

Constant Temperature Soldering Station SS-936A B

-

Constant temperature Solderinng Station SS-938A

-

LED Bulb Assembly Machine ABL-16

-

Solder Printing Machine

-

Heating Platform

-

Heating Platform

-

Solder Printing Machine